First. product features and uses:

This product is suitable for fixed transmission power transmission line or mobile electric connection cable with AC rated voltage of 0.6/1kV and below. The product has the characteristics of high temperature radiation resistance, cold resistance, acid and alkali resistance, corrosive gas and waterproof. The cable structure is soft and easy to lay. In the high temperature (cold) environment, the electrical performance is stable, the anti-aging performance is outstanding, and the service life is long. It is widely used in metallurgy, electric power, petrochemical, electronics, automobile manufacturing and other industries.

Second. product implementation standards:

Q/HHTZH001.1

Flame retardant and fire resistance test is carried out according to GB/T12666-2008 requirements

Third the use of characteristics

1. AC rated voltage: U0/U 0.6/1kV;

Maximum working temperature: 180°C;

Minimum ambient temperature: fixed laying -60°C;

2. The cable installation temperature should not be lower than -25°C;

3. The allowable bending radius of the cable: the minimum is 10 times the outer diameter of the cable.

Fourth. the basic model and name

model | name |

YGC | Silicone rubber insulated silicon rubber sheathed power cable |

YGCR | Silicone rubber insulated silicon rubber sheathed mobile power flexible cable |

YGCP | Silicone rubber insulated silicon rubber sheathed copper braided shielded power cable |

YGC22 | Silicone rubber insulated silicon rubber sheathed steel tape armored power cable |

JGG | Silicone rubber insulated silicone rubber sheathing installation line |

JGGR | Silicone rubber insulated silicone rubber sheath mobile mounting cable |

JGGP | Silicone rubber insulated silicon rubber sheathed copper braided shield mounting wire |

JHXG | Silicone rubber insulated motor lead wire |

Note: ZR is added to the flame retardant silicone rubber cable model, and the copper wire in the conductor core can be tinned.

V. Name of the code name:

Code | Code meaning |

Y | Serial code (mobile flexible cable) |

G | Silicone Rubber |

C | Heavy |

22 | Steel belt armor |

P | Copper braided shield |

R | Stranded conductor |

J | Motor lead |

Six. main technical indicators

1. The DC resistance of the finished cable conductor (according to the provisions of GB/T3956) refers to Table 1 and Table 2 of Appendix A.

2. The insulation resistance at 20oC is not less than 100MΩ·km.

3. The finished cable is subjected to AC 50Hz 3.5kV/5min voltage test without breakdown.

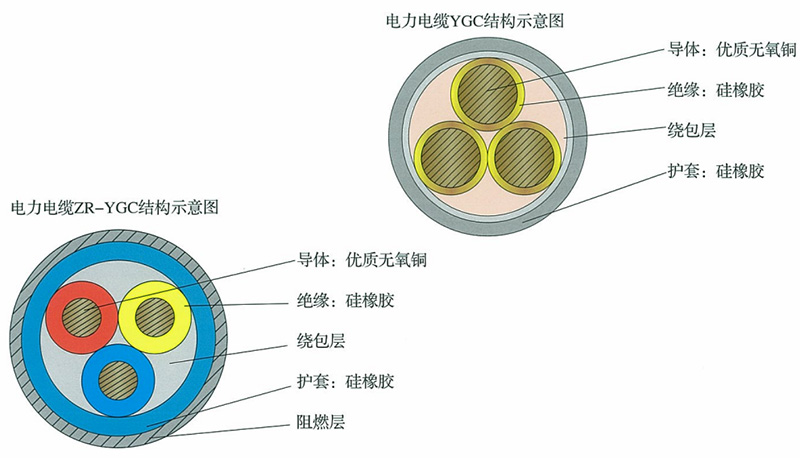

Product structure diagram