This product is designed according to MT818-2009 "Cables for Coal Mine", MCPTJ-1.9/3.3 meets the performance index of M188.4-2009.

range

This product is suitable for copper-core rubber sheathed metal shielded flexible cable for shearer and similar equipment with rated voltage U0/U for 1.9/3.3kV.

Type

Cable type is shown in Table 1.

Table 1

model | name | use |

MCPTJ-1.9/3.3 | Shearer metal screen rubber sheathed flexible cable | Power connection for shearer and similar equipment with rated voltage of 1.9/3.3kV and below |

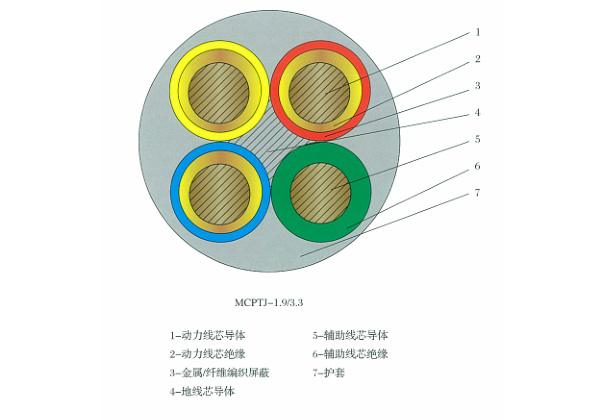

Cable structure diagram

specification

Table 2

Core number X conductor nominal cross section mm² | Nominal thickness mm | Cable outer diameter mm | 20 ° C ground wire conductor and shield parallel DC resistance maximum Ω / km | |||

Power core | Ground core | Auxiliary core | Power core insulation | jacket | MCPTJ-1.9/3.3 | |

3x35 | 1x35 | 1x16 | 3.0 | 5.5 | 51.6~54.6 | 0.50 |

skills requirement

conductor

The single conductor shall be tinned and the conductor shall comply with the provisions of 45.1 of MT818.1-2009. The surface of the power core conductor should be covered with an isolation layer. The DC resistance of the ground core conductor and the shield in parallel at 20 °C shall comply with the requirements of Table 3.

Note: Discoloration or embrittlement of the barrier layer after vulcanization is not evaluated.

insulation

The power core is made of ethylene-propylene rubber as the base material, and its performance should meet the requirements of XJ-30A in GB/T7594.8-1987. The tensile strength should not be less than 6.5MPa. After the insulated core is immersed in water for 12h, the cable shall be tested with a power frequency voltage of 6.8kV and 5min. There shall be no entry and exit breakdown during the test. The insulated core should be subjected to the insulation water absorption test. The capacitance increase rate of ≤10% is ≤10%, and the capacitance increase rate of 7-13% is ≤3%. The thickness of the insulation shall comply with the requirements of Table 2. The insulation resistance of the power core shall comply with the requirements of Table 3.

table 3

Core type | Nominal cross section mm2 | Insulation resistance minimum at 20 ° C MΩ / km |

Rated voltage 1.9/3.3kV | ||

Power core or paving core | 35 | 850 |

50 | 740 | |

70 | 630 | |

95 | 550 |

shield

The insulation shielding shall be a combined structure with a cladding + metal/fiber braid. The braided structure shall comply with the provisions of 5.4.4 of MT818.1-2009, and the braided copper wire shall comply with the provisions of Table 6 of MT818.1-2009.

Cable core

The position of the auxiliary core shall comply with the provisions of 5.4.3b) of MT818.1-2009, and the position of the ground core shall comply with the provisions of 5.4.4e) of MT818.1-2009. The strand pitch ratio of the core should be no more than 9.

jacket

If there is inner sheath, the inner sheath should meet the requirements of XH-03A type in GB/T7594.7-1987, and the outer sheath should meet the requirements of XH-03A in MT818.1-2009, and the tensile strength is not less than 5N/mm. The thickness of the sheath shall comply with the requirements of Table 2, and the color of the sheath shall be black.

Outer diameter

The average outer diameter of the cable shall be within the range listed in Table 2.

Working conditions

The rated working voltage U0/U is 1.9/3.3kV. The long-term operating temperature of the cable conductor is 90 °C, and the minimum bay radius of the cable is 6 times the diameter of the cable.