This product is designed according to MT818-2009 "Cables for Coal Mine", MY-0.38/0.66, MYP-0.66/1.14 meet the performance index of MT818.5-2009.

range

This product is suitable for rubber insulated rubber sheathed flexible cable for coal mine mobile equipment with rated voltage U0/U below 0.66/1.14kV.

Type

Cable type is shown in Table 1.

Table 1

model | name | use |

MY-0.38/0.66 | Mobile rubber flexible cable for coal mine | Power connection for various underground coal mining equipment with rated voltage of 0.38/0.66kV |

MY-0.60/1.14 | Mobile shielded rubber sheathed flexible cable for coal mine | Power connection for various underground coal mining equipment with rated voltage of 0.66/1.14kV |

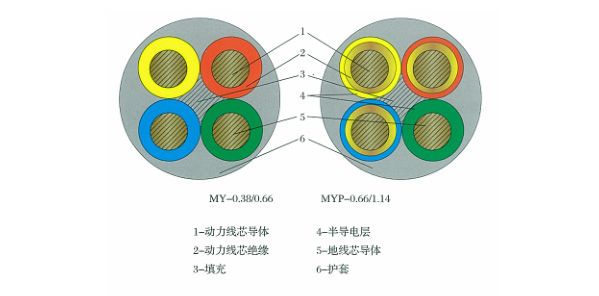

The cable can be divided into single core and 4-core (3+1) according to the number of cores. The structure of the 4-core cable is shown in the figure below.

specification

Cable regulations shall comply with Table 2, Table 3, and Table 4.

Table 2

Core number X conductor nominal cut mm² | Nominal thickness mm | Cable outer diameter mm | |

Power core | Power core insulation | jacket | MY-0.38/0.66 |

1x4 | 1.4 | 1.5 | 8.0~10.0 |

table 3

Number of cores x conductor nominal cut mm² | Nominal thickness mm | Cable outer diameter mm | ||

Power core | Ground core | Power core insulation | jacket | MY-0.38/0.66 |

3x4 | 1x4 | 1.4 | 3.5 | 19.0~22.5 |

Table 4

Number of cores x conductor nominal cut mm² | Nominal thickness mm | Cable outer diameter mm | ||

Power core | Ground core | Power core insulation | jacket | MY-0.66/1.14 |

3x10 | 1x10 | 1.8 | 4.5 | 30.0~35.0 |

skills requirement

conductor

The single core of the conductor is allowed to be tinned, and the guide should be in accordance with 5.1 of MT818.1-2009. The conductor surface may be provided with an isolation layer.

Note: Discoloration or embrittlement of the barrier layer after vulcanization is not evaluated.

insulation

The power cable core shall be specified in accordance with the XJ-30A type in GB/17594.8-1987, and the tensile strength shall not be less than 6.5 MPa. MY-0.38/0.66 type cable ground core conductor, such as extruded insulation, performance should meet the requirements of XJ-30A type in GB/T7594.8-1987, tensile strength should not be less than 6.5MPa. The insulation thickness is specified in Table 2, Table 3 and Table 4; the insulation resistance of the cable at 20 °C shall comply with the requirements of Table 5.

table 5

Power wire core nominal cross section mm2 | Minimum insulation resistance MΩ·km at 20°C | Power wire core nominal cross section mm2 | Minimum insulation resistance MΩ·km at 20°C | Power wire core nominal cross section mm2 | Minimum insulation resistance MΩ·km at 20°C |

4 | 600 | 35 | 250 | 150 | 180 |

Cable core

The position of the ground core should be in accordance with the provisions of 5.4.4b) in MT818.1-2009. The twisted pitch ratio of the multi-core cable core: the power core cross section 4 ~ 16mn2 should not More than 12, the power core core section 25 ~ 400mm 2 should be no more than 14.

jacket

If the cable has an inner sheath, the rubber sheath shall not be lower than the XH-03A type specified in GB/T7594.7-1987. The outer sheath of the cable shall comply with the XH03A type specified in GB/T7594.7-1987, and the tear strength shall not be less than 5N/mm. The thickness of the outer sheath of the cable shall be in accordance with the provisions of MT818.1-2009 and Tables 2, 3 and 4 of this part.

Working conditions

The rated voltage U0/U is 0.38/0.66 and 0.66/1.14kV, the long-term operating temperature of the cable conductor is 90 °C, and the minimum bending of the cable is 6 times the diameter of the cable. The ground core of the cable should be well grounded.